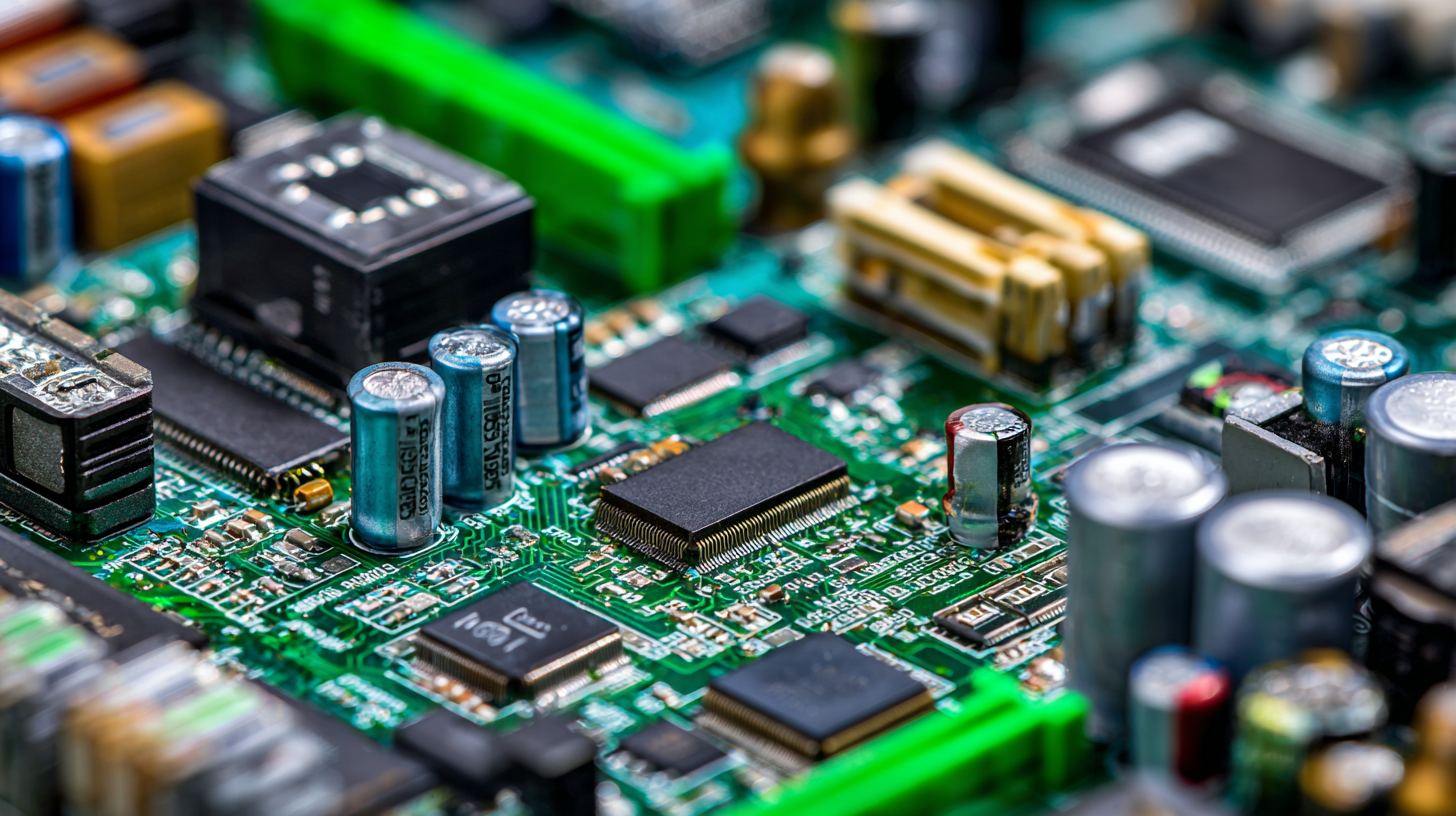

Mastering Electronic Board Manufacturing Techniques A Comprehensive Tutorial for Industry Professionals

In the rapidly evolving landscape of technology, mastering electronic board manufacturing techniques has become crucial for industry professionals seeking to stay ahead of the curve. This comprehensive tutorial will delve into the best practices and innovative methods that define the electronic board manufacturing process, encompassing everything from design and prototyping to production and quality assurance. With the increasing demand for high-performance electronics, understanding the intricacies of electronic board manufacturing is not just advantageous; it is essential for success in the competitive market. This blog aims to equip professionals with the knowledge and skills needed to navigate the complexities of this vital sector, ensuring they can deliver top-notch products that meet the highest standards of quality and efficiency.

Checklist for Setting Up an Efficient PCB Design Workflow

When it comes to setting up an efficient PCB design workflow, having a structured checklist can make all the difference in streamlining the process. First and foremost, establish a clear set of design requirements and specifications before you begin the design phase. This foundational step ensures that everyone on your team is aligned on the project goals, which can prevent costly revisions later on.

Tip: Utilize design software that offers automated checking features. This can save you time and reduce human error by flagging potential issues in real-time.

Next, prioritize communication among team members. Regular check-ins and updates are crucial in addressing any challenges that arise during the design cycle. Implementing collaborative tools can facilitate quicker feedback and streamline the decision-making process.

Tip: Maintain a centralized storage for all design files and documentation. This not only improves accessibility but also fosters a more organized workflow, ensuring that everyone is working with the most up-to-date information.

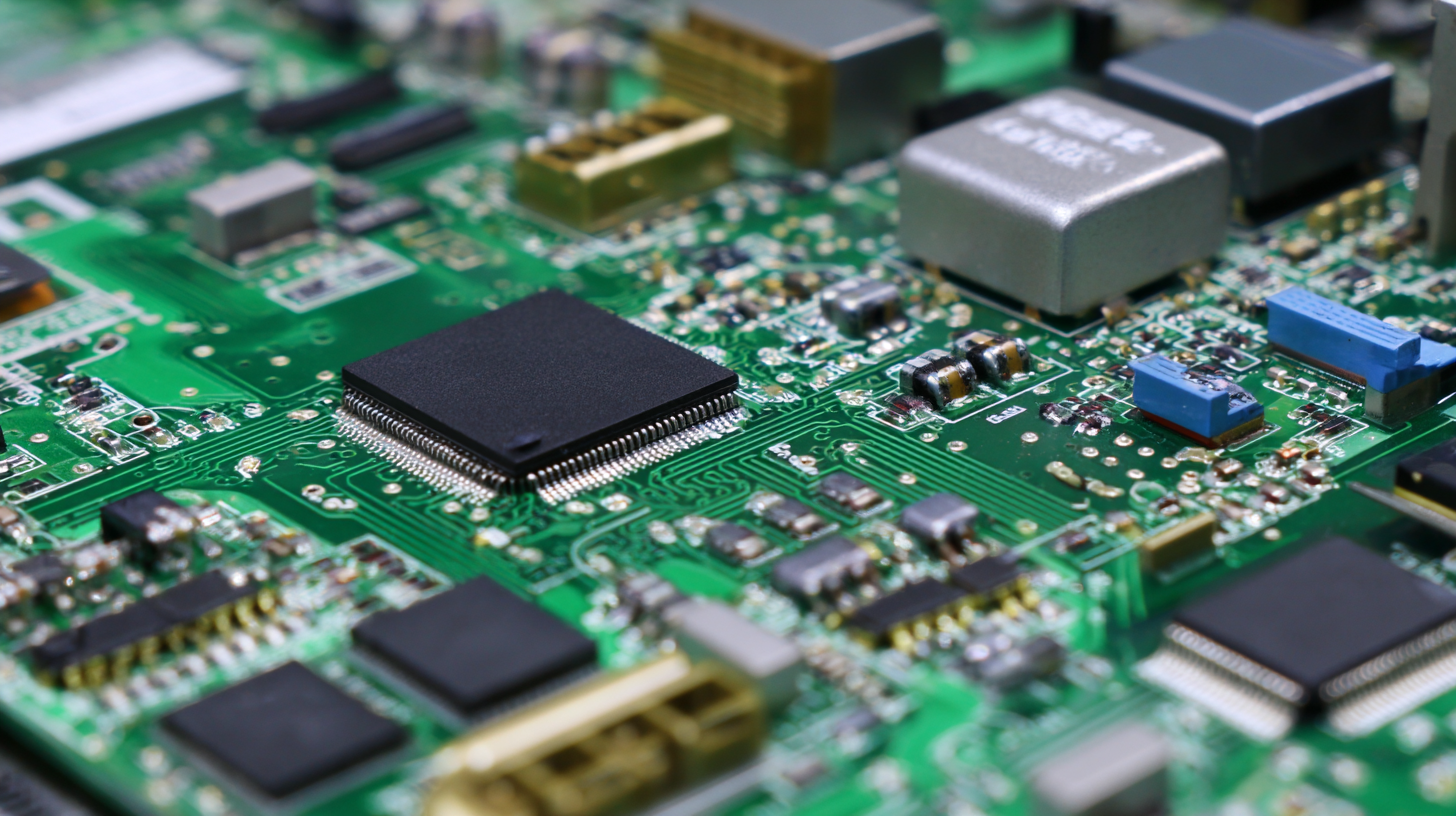

Essential Tools and Software for Electronic Board Manufacturing

In the realm of electronic board manufacturing, leveraging essential tools and software is crucial to optimizing production processes. With the recent guidelines issued by the Ministry of Industry and Information Technology, professionals are encouraged to embrace technological upgrades that enhance efficiency and reduce energy consumption. By 2027, these advancements are expected to significantly impact the automotive and component manufacturing sectors, making it imperative for industry players to stay ahead of the curve.

When selecting software solutions, prioritize those that offer robust design capabilities and seamless integration with manufacturing processes. Tools like advanced CAD systems can streamline the design phase, ensuring precision and reducing errors. Additionally, employing simulation software can help foresee potential issues in the production line, enabling proactive measures to avoid costly delays.

Another key aspect is the investment in automated manufacturing equipment, which can lead to consistency and lower production costs. Implementing automation not only boosts efficiency but also allows for better allocation of human resources towards more complex tasks. By focusing on these essential tools and adopting innovative software solutions, electronic board manufacturers can achieve a competitive edge in an ever-evolving industry landscape.

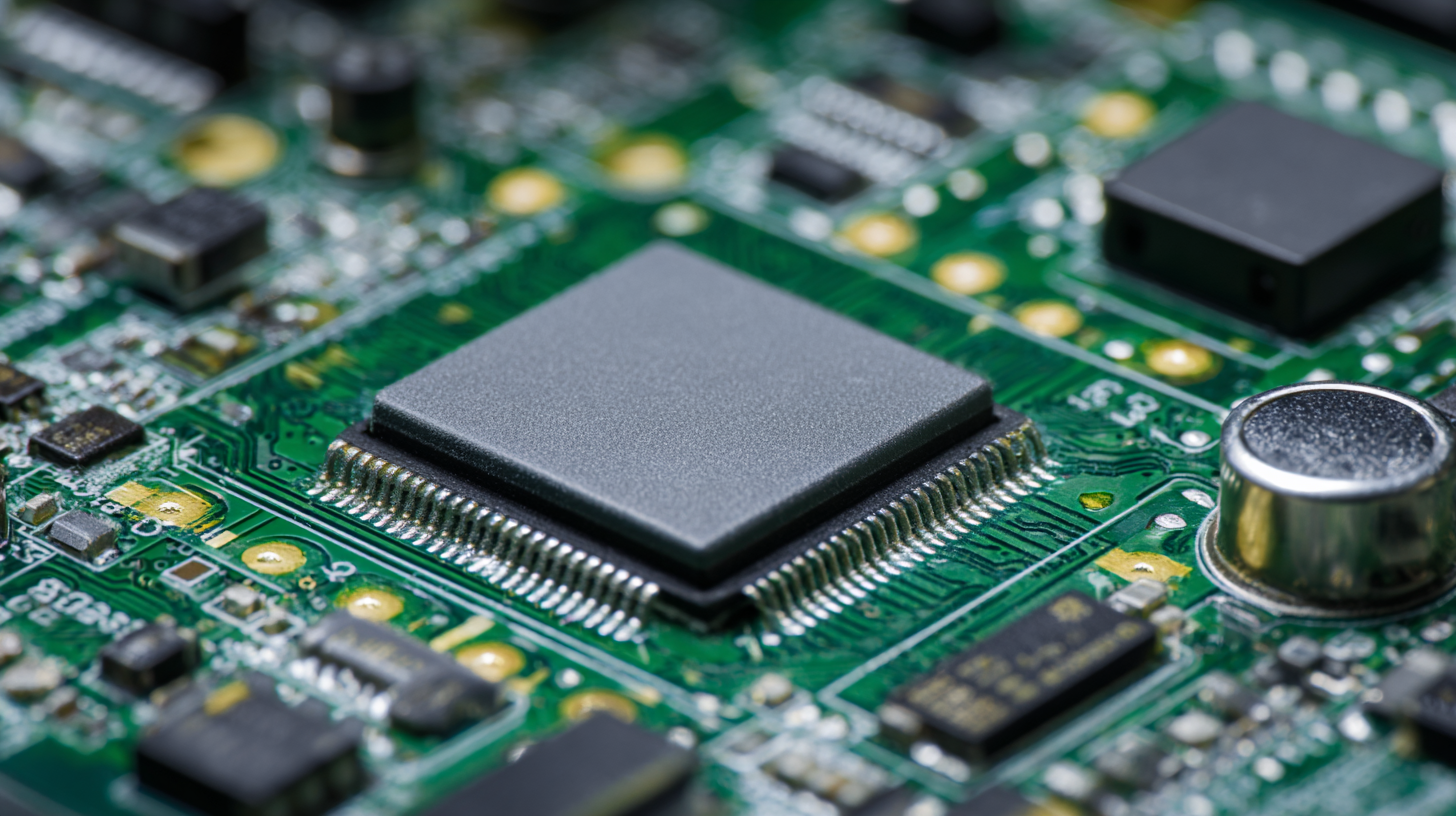

Key Quality Control Steps in the PCB Production Process

In the realm of electronic board manufacturing, quality control is paramount to ensure the reliability and functionality of printed circuit boards (PCBs). Key steps in the PCB production process include meticulous inspections at various stages. Beginning with the incoming material inspection, manufacturers must verify the quality of the raw materials, such as copper-clad laminates and solder masks. Utilizing advanced techniques like X-ray inspection and optical scanning, any defects can be identified early, minimizing the risk of costly errors downstream.

As the production progresses, the next critical step involves monitoring the etching and plating processes. It's essential to control parameters such as temperature, time, and chemical concentrations to achieve optimal results. Implementing real-time quality monitoring systems allows for immediate detection of anomalies, ensuring that boards maintain consistent thickness and pattern accuracy. Following assembly, a final thorough inspection using automated optical inspection (AOI) and functional testing is crucial to confirm that each PCB meets industry standards. These quality control measures not only enhance product reliability but also help manufacturers uphold their reputation in a competitive marketplace.

Common Manufacturing Issues and How to Troubleshoot Them

In the world of electronic board manufacturing, addressing common manufacturing issues is crucial for maintaining efficiency and quality. Problems such as misalignment, poor soldering, and component damages can be frequent and disruptive. Troubleshooting these issues often requires a systematic approach, drawing on both technical skills and industry knowledge.

One effective method is to implement a root cause analysis for each issue encountered. By breaking down the problem into its fundamental components, you can identify the underlying causes and develop targeted solutions. For example, if misalignment occurs, check both the accuracy of the assembly jigs and the calibration of placement machines. Regular maintenance of equipment can prevent many problems before they affect production.

Tip 2: Utilize lean methodologies to streamline processes. Engaging your team in continuous improvement initiatives can enhance problem-solving capabilities and lead to a more robust manufacturing environment.

By applying these strategies, you can effectively troubleshoot and resolve common manufacturing challenges, ensuring a smoother operation moving forward.

Final Inspection Checklist Before PCB Assembly and Delivery

When it comes to electronic board manufacturing, the final inspection before PCB assembly and delivery is a critical step that ensures quality and reliability. Professionals must adhere to a thorough checklist to avoid potential issues down the line. Key elements of this checklist include verifying the integrity of the design files, inspecting the physical condition of the boards, and confirming proper component placement. Each step not only helps in identifying defects early but also minimizes the risk of failures during the end-use of the product.

Additionally, it's essential to assess soldering quality and board cleanliness before proceeding with assembly. Issues like solder bridging or contamination can jeopardize performance and longevity. The checklist should also encompass testing for electrical connectivity and visual inspections for any visible defects, such as scratches or traces of foreign material. These practices are vital as they contribute to the overall robustness of the finished product, ensuring that it meets industry standards and customer expectations. By embracing a comprehensive final inspection checklist, industry professionals can significantly enhance the quality and reliability of their PCB assemblies.

Additionally, it's essential to assess soldering quality and board cleanliness before proceeding with assembly. Issues like solder bridging or contamination can jeopardize performance and longevity. The checklist should also encompass testing for electrical connectivity and visual inspections for any visible defects, such as scratches or traces of foreign material. These practices are vital as they contribute to the overall robustness of the finished product, ensuring that it meets industry standards and customer expectations. By embracing a comprehensive final inspection checklist, industry professionals can significantly enhance the quality and reliability of their PCB assemblies.